Our State-of-the-Art Equipment for Electronics Manufacturing

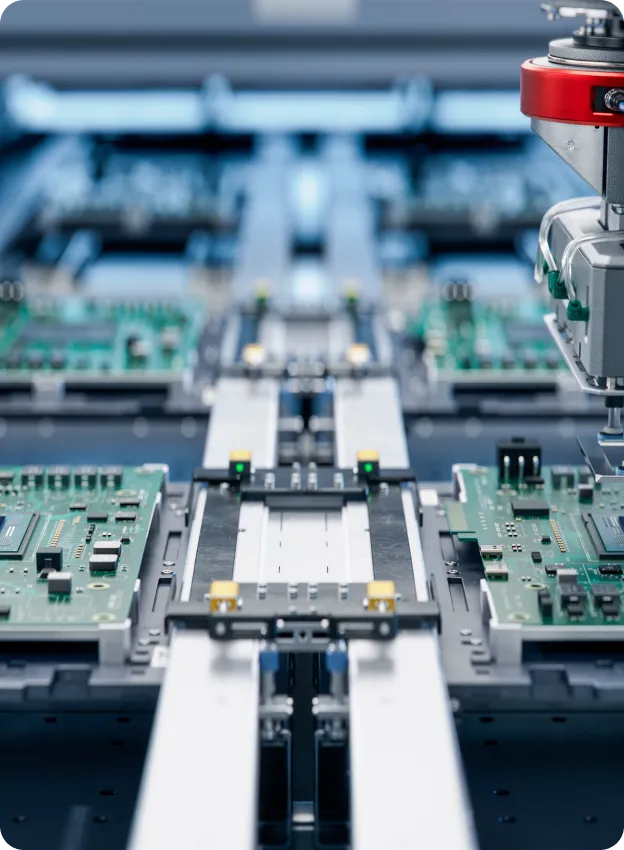

Discover our commitment to precision with a visit to our 42,000-square-foot facility at S&K Electronics, Inc. We are strategically located between Missoula and Kalispell, MT, in the heart of the Mission Valley. Our facility is spread across three buildings and houses advanced automated equipment for manufacturing, inspection, and testing. In addition, we have a fully equipped machine shop to support our capabilities in delivering high-quality custom cable assemblies and wire harness assemblies, electromechanical box builds, and circuit card assemblies, all on schedule.

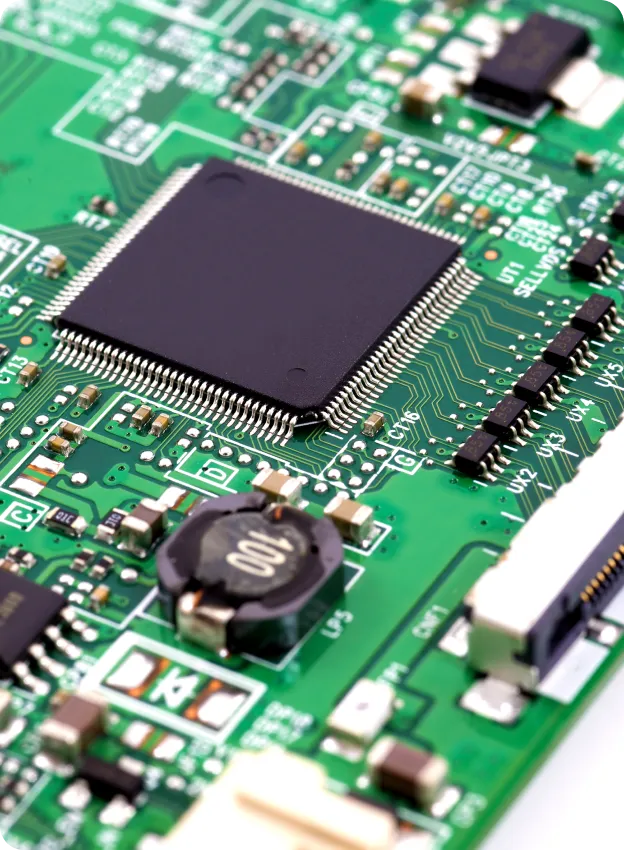

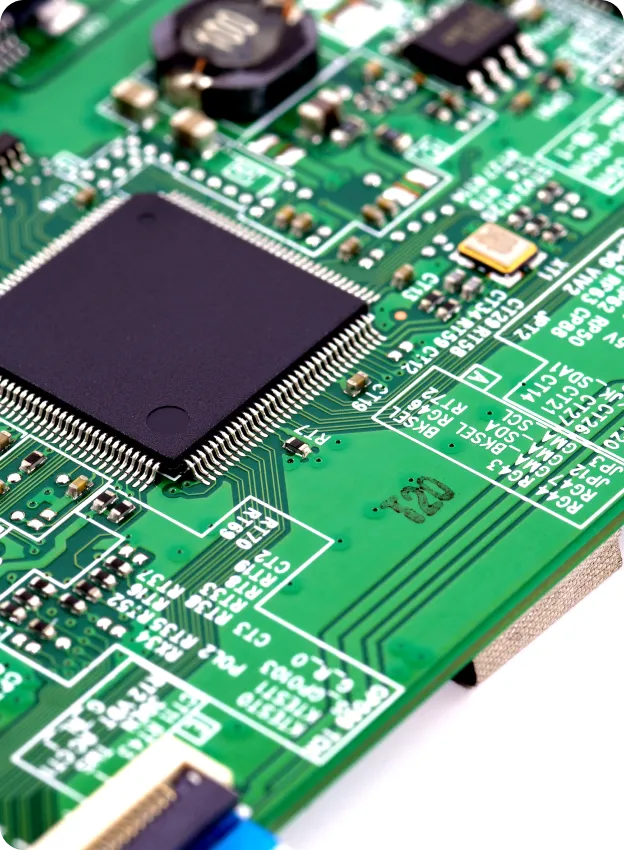

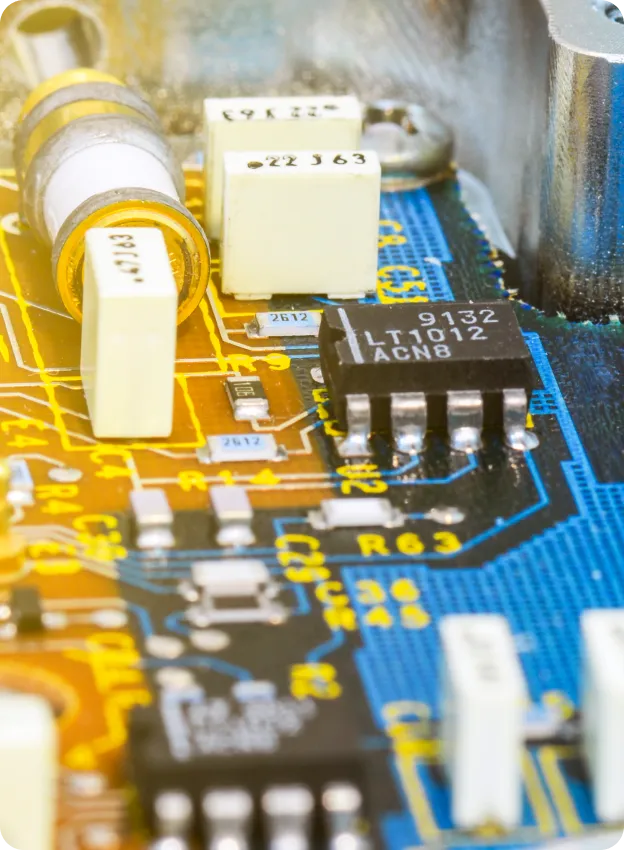

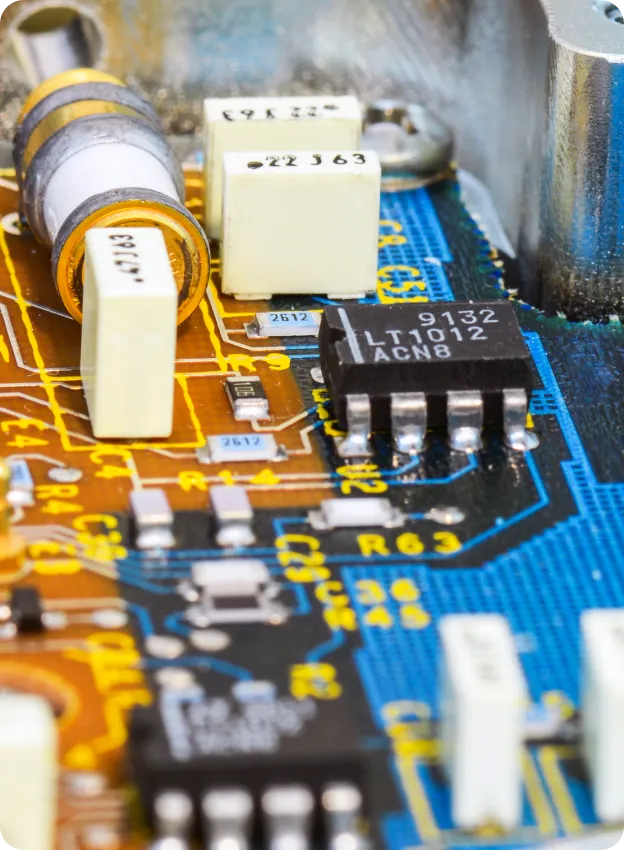

Circuit Card Manufacturing Equipment

Manufacturer And Model Overview

We use a variety of advanced equipment to ensure precision and quality in every circuit board assembly project:

Cabling

Equipment Overview

We utilize a range of top-tier equipment for high-precision cable manufacturing:

RF Testing Capabilities

We specialize in RF testing, including insertion loss and VSWR measurement up to 40 GHz using:

Our advanced equipment ensures precision and reliability in every cable assembly and testing process.

Inspection and Testing

Model Description And Manufacturer Overview

Our comprehensive inspection and testing capabilities are supported by high-precision tools:

Additionally, we use standard bench test equipment to support custom functional testing.

Machine Shop

Manufacturer and Model Description

Our machine shop is equipped with advanced tools to support precision manufacturing:

These tools allow us to deliver high-quality, precise manufacturing solutions.

Precision Electronics Assembly With Proven Expertise

With 40 years of experience, we specialize in producing high-quality cable and wire harness assemblies, electromechanical box builds, and circuit card assemblies. Our electronics manufacturing services at S&K Electronics, Inc. include surface mount, through-hole, mixed technologies, selective wave, hand add, and wave soldering.

Innovation and Reliability in Every Product

Backed by a skilled workforce and cutting-edge engineering, we prioritize delivering exceptional products on time, every time. Flexibility, scalability, and innovative manufacturing processes ensure we exceed our clients’ expectations consistently.

Circuit Card Assemblies

S&K Electronics, Inc. provides a range of circuit card assembly (CCA) solutions tailored to meet diverse product needs. Our advanced methods include:

All units assembled in a controlled electrostatic discharge (ESD) environment.

Wiring Solutions

At S&K Electronics, Inc., our cable and wire harness assembly processes utilize advanced automated equipment from Schleuniger. These tools efficiently cut, strip, and, if necessary, mark wires.

Electromechanical Box Builds

We deliver complete electromechanical assembly solutions by integrating circuit card sub-assemblies, wiring, and metal or plastic enclosures. We specialize in projects ranging from straightforward wire and crimp-pin assemblies to complex interconnect boxes involving over 20 connectors and up to 500 individual wires. Our assemblies meet both military and commercial standards.

Seamless Integration into Electromechanical Box Builds

Our dedicated team oversees the manufacturing of all subassemblies, ensuring seamless integration and the timely delivery of high-quality products every time.

Trusted Provider of NBC Heater Units

For over 40 years, S&K Electronics, Inc. has been a trusted supplier to the Department of Defense, delivering over 250,000 NBC (Nuclear-Biological-Chemical) Heater assembly units. Designed and qualified by our in-house experts, this electromechanical assembly is built to meet rigorous government specifications. Our continuous use of lean manufacturing techniques has ensured that these units remain cost-effective while maintaining the highest quality standards.

NBC Heater Key Specifications

Additional Value-Added Processes

We are capable of performing a variety of value-added processes, ensuring each NBC Heater unit is tailored to meet specific operational needs.